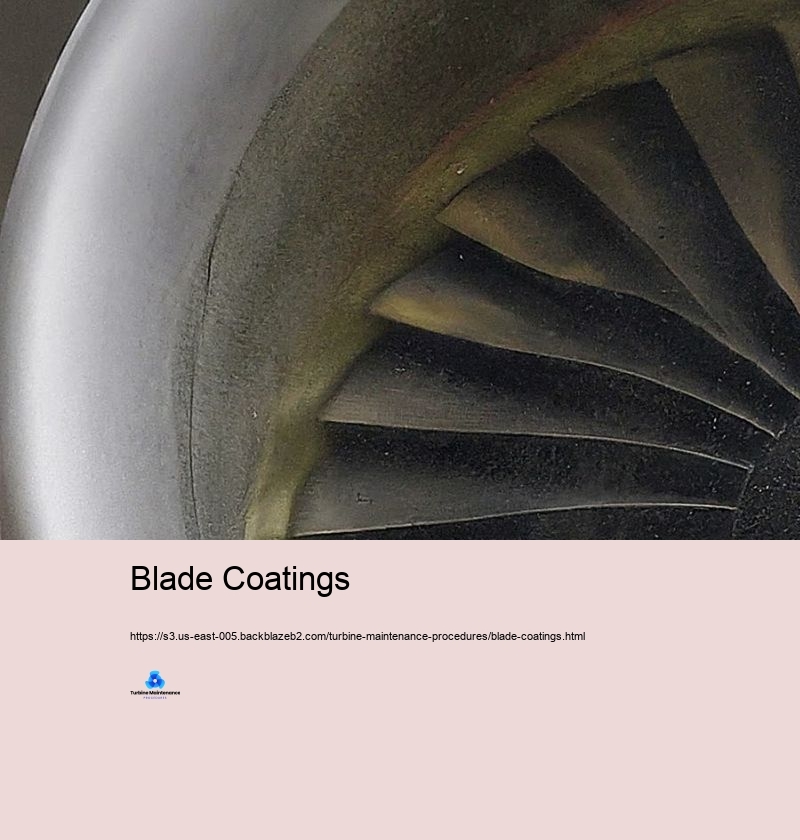

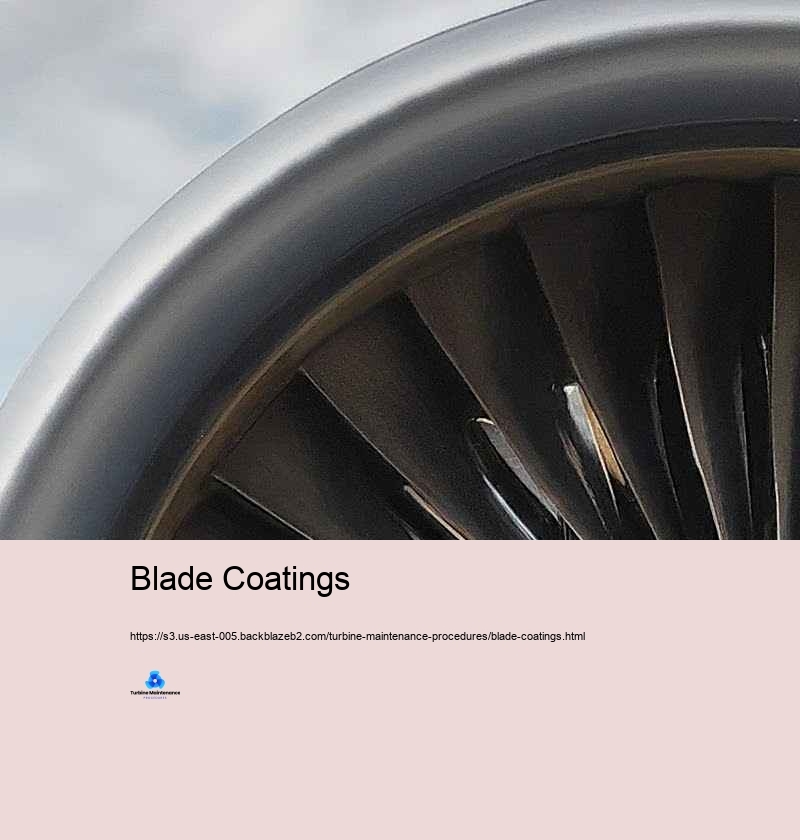

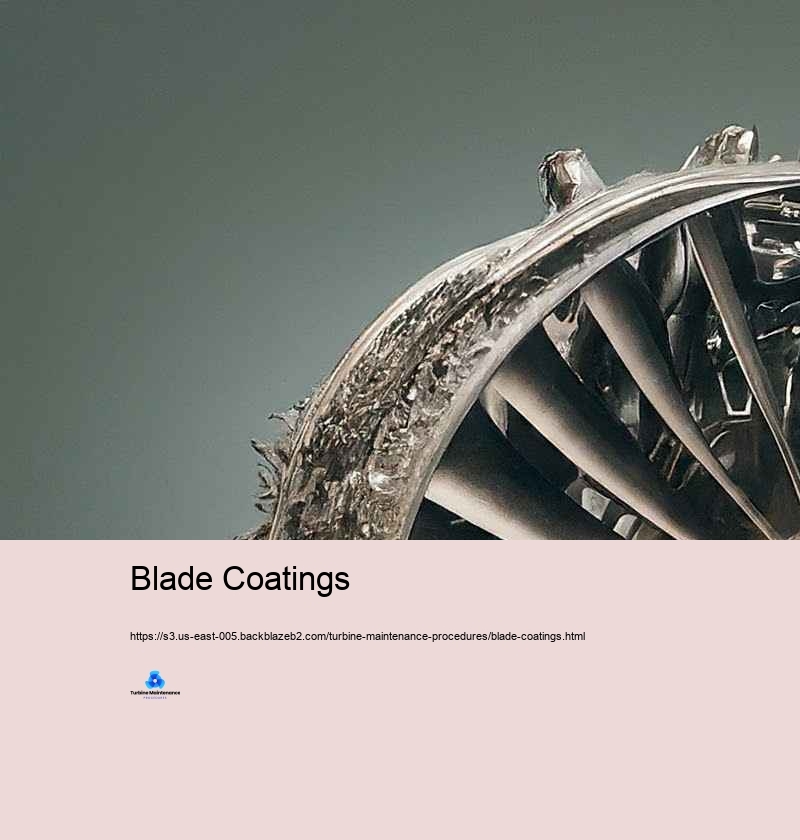

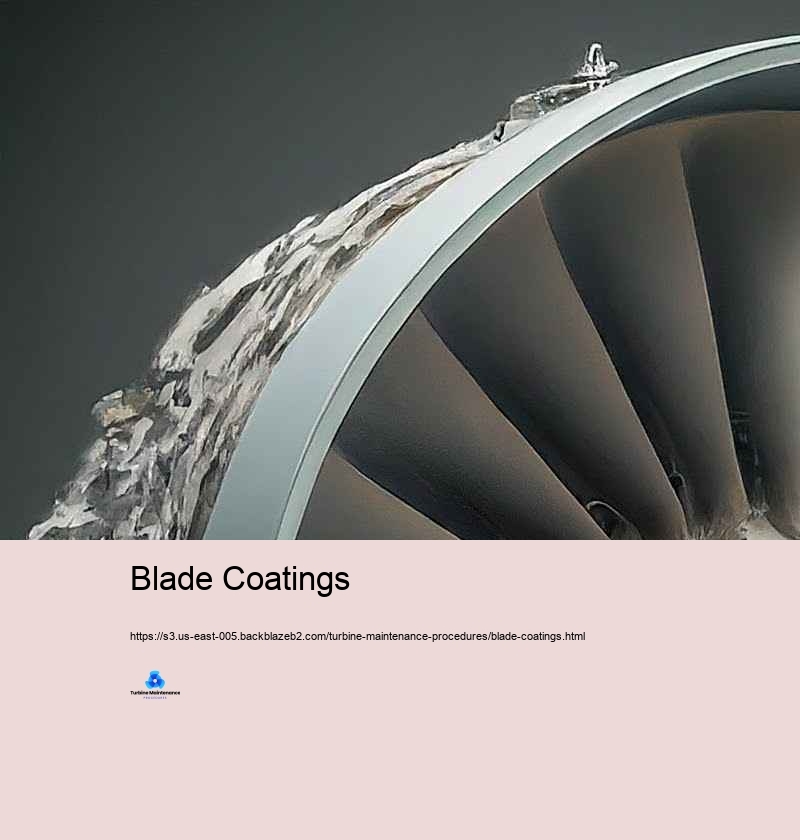

Blade Coatings

Cooling System Maintenance

Turbine maintenance is a vital facet of power generation, industrial procedures, and many various other applications where generators play an important function. Ideal maintenance makes sure ideal performance, lengthens the lifespan of the devices, and avoids pricey failures. This introduction to turbine maintenance discovers the vital concepts and methods crucial for maintaining these intricate tools efficiently. At its core, turbine maintenance is about preserving the security and performance of the turbine system. Wind turbines, whether heavy steam, gas, or hydraulic, are cutting-edge items of equipment that change energy from a fluid (vapor, gas, or water) right into power. The high-speed transforming, serious temperature levels, and stress associated with their procedure make regular and detailed maintenance vital. Among the standard ideas in turbine maintenance is preventative maintenance. This aggressive technique involves regularly organized evaluations, cleaning, and minor fixings to stay clear of considerable failings prior to they occur. Precautionary maintenance commonly contains jobs such as lubricating bearings, analyzing and readjusting clearances, examining blades for wear or damage, and keeping an eye on resonance levels. By settling little problems early, preventative maintenance can significantly reduced the risk of ruining failings and expand the turbine's functional life. Condition-based maintenance is one more vital idea that has acquired prominence with the advent of innovative keeping an eye on contemporary technologies. This technique depends upon real-time data from picking up units and keeping track of systems to identify when maintenance is required. Standards such as resonance, temperature level, tension, and oil condition are constantly monitored. When these requirements differ routine varieties, it programs feasible issues that need emphasis. Condition-based maintenance makes it possible for even more targeted and effective maintenance tasks, reducing unnecessary downtime and taking full advantage of resource allowance. Expecting maintenance takes condition-based maintenance a step better by utilizing info analytics and expert system formulas to projection when failings are most likely to happen. By analyzing historical details and existing running problems, anticipating maintenance systems can forecast potential issues prior to they appear as apparent troubles. This approach enables maintenance groups to prepare interventions at the most appropriate times, reducing disruption to procedures and maximizing the performance of maintenance tasks. Placing is a vital method in turbine maintenance. Proper placement of the turbine shaft with the generator or driven devices is essential for smooth treatment and long life. Imbalance can result in too much resonance, quickened wear of bearings and seals, and lowered efficiency. Regular positioning checks and changes, frequently making use of laser placement gadgets, are a standard component of turbine maintenance regimens. Harmonizing is an additional necessary aspect of turbine maintenance. The high-speed rotation of turbine aspects means that even small disparities can cause substantial resonance and put on. Dynamic balancing of blades and impellers is performed to make certain smooth treatment. This procedure consists of including or eliminating percentages of weight at particular points to accomplish optimum balance. Regular resonance evaluation assists identify inequality troubles early, permitting prompt enhancements. Assessment and cleansing of turbine blades are crucial maintenance techniques. Blades can have problem with various problems such as disintegration, deterioration, fouling, or physical damage. Regular assessments, usually utilizing borescopes or various other non-destructive screening techniques, assistance establish these issues. Cleansing of blades, which could involve chemical cleansing or mechanical approaches like grit blasting, assists preserve wind immune effectiveness and stops efficiency degradation. Lubrication management is a critical aspect of turbine maintenance. Proper lubrication of bearings, gears, and other transferring parts is vital for decreasing rubbing and put on. This includes not only making certain an ideal supply of lube but furthermore keeping an eye on its premium. Oil analysis is a common technique that aids spot impurities, use bits, and alterations in oil properties that might show creating issues in the turbine system. Seal maintenance is an extra vital strategy. Seals quit leakage of functioning fluids and lubricating compounds, and their failing can cause substantial performance losses and prospective safety and security and protection dangers. Routine evaluation and replacement of seals, especially in high-pressure or high-temperature locations, is a common part of turbine maintenance routines. Control system maintenance is significantly essential as generators end up being a great deal even more automated and online regulated. This involves regular checks and calibration of noticing systems, actuators, and control shutoffs. Software application updates and cybersecurity steps are additionally critical elements of modern turbine control system maintenance. Security and protection is exceptionally crucial in all turbine maintenance tasks. Wind wind turbines entail high powers, severe temperatures, and perhaps unsafe products. Strict adherence to safety and security and protection techniques, including lockout/tagout procedures, constrained room entry procedures, and ideal usage personal safety gadgets (PPE), is important. Safety and protection training and routine document program for maintenance employees are essential techniques in turbine maintenance programs. Documentation and record-keeping are essential methods in turbine maintenance. In-depth logs of all maintenance jobs, consisting of inspections, repair services, and component alternatives, provide essential historical information for trend evaluation and future maintenance planning. Lots of firms currently make use of electronic maintenance management systems (CMMS) to improve this treatment and assist in data evaluation. Training and ability advancement of maintenance workers is a recurring method in turbine maintenance. Blade Coatings As turbine contemporary technologies development, maintenance methods and gadgets likewise advance. Regular training programs make certain that maintenance personnel are current with the current maintenance techniques, analysis devices, and safety and security procedures. Ecological elements to consider are coming to be significantly essential in turbine maintenance. This consists of correct handling and disposal of harmful items like used oils and cleansing chemicals. Great deals of maintenance methods presently focus on reducing environmental impact while making sure ideal turbine effectiveness.

Blade Coatings - Ultrasonic Testing

- Cooling System Maintenance

- Ultrasonic Testing

- Emergency Repair Protocols

- Condition Monitoring Systems

- Maintenance Guidelines

- Downtime Management

- Control Systems

Blade Coatings